updated: 2018-11-21 a

————————————————————————————————————————

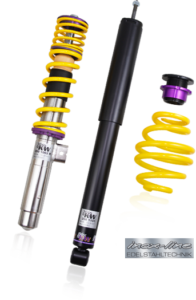

Because there´s much more request for sports suspension we´ve made some different kits to make the work more easy:

KW-sports suspension- kit ” piccolo” : b-fw-70 / euro 990.-

includes KW sports-suspension, upper strut bearings, inner driveshaft sleeves made in nitril

KW-sports suspension- kit “grande” : b-fw-071 / euro 1030.-

includes KW sports-suspension, upper strut bearings, inner driveshaft sleeves made in nitril. additional to kit piccolo, also the sleeves for the outside are included ( high quality )

KW-sports suspension- kit “maxi” : b-fw-072 / euro 1200.-

same parts as in kit grande, additional with wheelspacer kit ( 10 or 15mm for front, 20 or 25mm for rear – measure means per wheel).

chassis

Beside engine and brakes, the possible driving fun, which one can have with the Barchetta, depends of course also to a large extent on the chassis. A “rocking load” obviously prevents you from taking a fast turn (and in our opinion this is exactly the Barchetta’s showpiece discipline …).

This does not mean that we want to impose the installation of a sports chassis on every customer.

But also for the “normal driver” a good handling is important. Since almost all Barchette have meanwhile achieved mileages of over 100,000 km, it is quite true that the first chassis elements are worn out.

Here are a few possibilities:

A) Replacing front and rear shock absorbers with springs: Replacing only single components would not be the best solution. The overall chassis geometry remains the same, the driving comfort corresponds to that of the standard chassis. In this case we recommend the installation of Bilstein elements: These provide very good feedback with regard to driving behaviour.

B) Installation of a sports suspension with thread for individual adjustment of the front depth (“thread chassis”): The ground clearance at the lowest point (at the bottom of the oil pan) is then still 7.5-8 cm – if the suspension has been turned all the way down …

Meanwhile we also install the threaded chassis in many customer vehicles, which should only be lowered discreetly. The plus in terms of damping and feedback when cornering compared to a rigid non-threaded suspension convinces (almost) everyone.

There are two brands here that we recommend with a clear conscience and that we mainly install:

1. The cheaper brand ST-X (produced by KW, see under 2.), which has the same tuning as the KW chassis itself.

From the outside you have to make some slight compromises compared to the KW chassis: The elements are galvanized, the adjusting thread is coarser. Otherwise the manufacturing leaves nothing to be desired.

2 An increase is the original chassis of the premium brand KW. For the Barchetta a stainless steel version is available:

Important note: With both threaded suspensions modified upper strut bearings must be mounted, an installation with the series bearings is not possible! Therefore we offer the suspensions with the necessary parts as a kit:

PLEASE NOTE : FITS ONLY IN KW / STX SUSPENSION !

b-fw-034 / euro 85.-

We are an official KW-/ST-X partner: So we don’t just offer these chassis for the Barchetta – for other vehicles we will be happy to make you an offer including installation on request.

Camber backfill screws

Normally the front suspension struts have two circular holes for the fixing screws on the wheel carrier (except for the KW / STX elements – where elongated holes allow the camber value to be changed). In order to adjust the chassis to our camber values, the camber offset screws shown below are fitted with an eccentric:

b-fw-050 / euro 68.- ( set)

Stability – strut brace

Additional stability is provided by a front strut brace. This prevents the two wheel houses from twisting against each other. The installation of a strut brace is noticeable for every driver: the driving behaviour is improved even further. (Actually, this additional component is recommended for every front-wheel-drive car that is driven fast.)

In addition, a strut brace is also available for the rear – but is not so often used:

NEW:

Steel strut brace, suitable for all Barchette, specially designed also for mounting on models with plastic airbox (VIS, including M2 models) – made by DSM and with a high-quality look due to black satin plastic coating:

b-car-conc-011 / euro 115.-

Wider …

Another chassis theme is widening the track. On the one hand the driving behaviour (again especially when cornering) is already improved (stabilised) by small changes in the track width, on the other hand wider track plates are often mounted because of the wider optical appearance.

Important and an advice: by our selection of the plates we take care for a very good centre of the wheel at the plate (otherwise the wheel would be disaxed and there wouldn´t be a good balance). also we give the advice to use plates starting at a thickness of 20 milimeters which are mounted fix at the wheel-hub. the advantage is an easier mounting of the wheel and using bolts with a normal length. the additional expenditure is worthwhile.

It is advisable to stay with the front wheels between 5 and 10 milimeters per wheel less than at the rear wheels. as a result, the handling is more stable at high cornering speeds and the feedback from the front is clearer.

A selection of track plates:

Thickness 10mm per wheel / b-fw-001 / Euro 55.- (set 2 pieces)

Thickness 12mm per wheel / b-fw-073 / Euro 60.- (set 2 pieces)

Thickness 15mm per wheel / b-fw-051 / Euro 65.- (set 2 pieces)

Thickness 20mm per wheel with thread u.retaining screws / b-fw-002 / Euro 150.- (set)

Thickness 25mm per wheel with thread u. retaining screws / b-fw-052 / Euro 156.- (set)

Thickness 30mm per wheel with thread u. retaining screws / b-fw-035 / Euro 162.- (set)

Other versions available – please inquire if necessary.

The matching wheel bolts are also available from us. Please request this directly from us.

Technical tip: We often move the standard 5 mm track plates, which are mounted on the rear axle as standard, to the front axle and then add wider wheel plates at the rear. Their width must then also depend on the offset of the mounted rim.

Since all suspension components must fit together as a package, it is best to call us in advance!